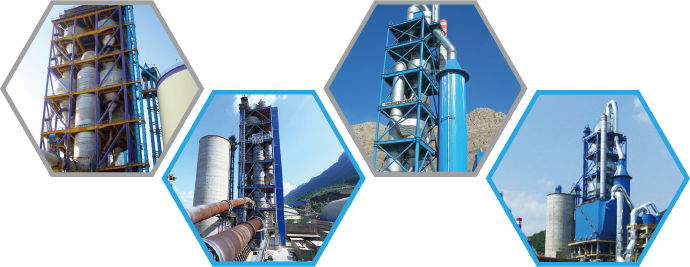

RF New High-efficiency Cyclone Preheater with Pre-calciner System

Lower dust

100% Significant resistance reduction

High separation efficiency of C1 cyclone (above 95%)

NOx reduction

Increased heat exchange efficiency

100% burning rate of anthracite

Y-series Rotary Kiln

Product Features

Self-aligning sliding bearing structure

Simple structure and stable operation

High efficiency and low abrasion

Easy replacement of floating plates

Hydraulic thrust roller device

Centralized air supply from centrifugal fan

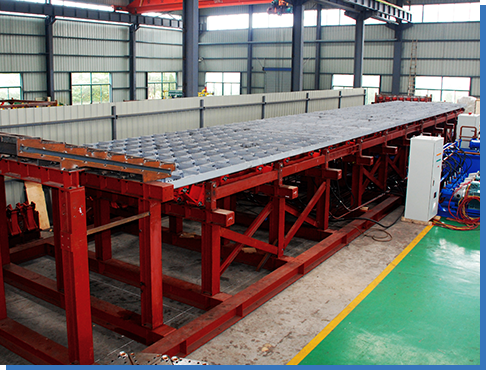

Cooler

Advantages

Height reduction by 2-3 meters

Grate plates free of abrasion

No leakage beneath grate plates

Progressive flow control valves

Unique support structure

Unique conveying method

Inlet fixed section with equal dynamic design

Modular design

VRM-Series Vertical Mills

Taizishan Cement Co., Ltd., Gansu Province

Bijie Cement Plant, Guizhou Province, Technical Upgrade Project

Huong Duong Cement Co., Ltd. in Vietnam

Hong’an Cement Co., Ltd., Yunnan Province

Qianxi Tianrui Cement Co., Ltd., Guizhou Province

Xuan Thanh Investment Construction and Development Co., Ltd. in Vietnam

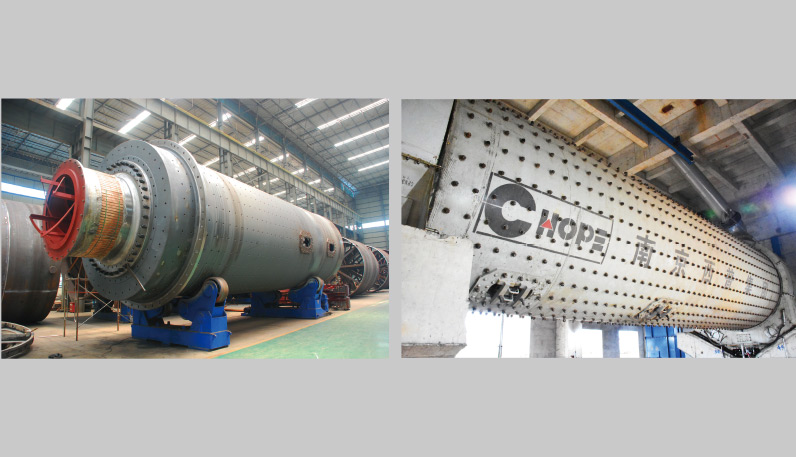

Tube Mill

Characteristic

Strong raw material adaptability. The drying capacity of air-swept mill and raw mill can be determined as per the moisture of raw material.

Different design plans for different grinding process.

The feeding device of air-swept mill adopts special “louver” structure to prevent blockage.

Types of liners are minimized with optimized and standardized mill liners, making purchase easier.